Product Description

Coupling,

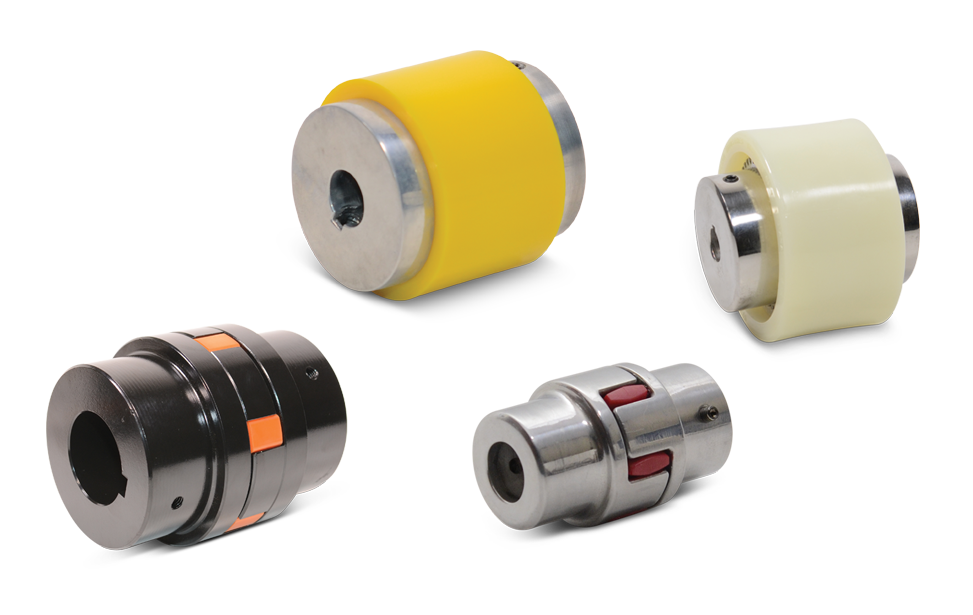

1. The couplings offer a range of hub and element selection to meet different demands.

2. They can absorb shock and cater for incidental misalignment and damp out small amplitude vibrations.

3. NBR, Urethane, Hytrel elements.

4. Customized requirement is available.

Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling: including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling,

Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint; 6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack.

8. Other customized Machining Parts according to drawings (OEM) Forging, Casting, Stamping Parts.

PACKING

| Packaging | |

| Packing

|

We use standard export wooden case, carton and pallet, but we can also pack it as per your special requirements. |

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTORY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Best Practices for Installing a Motor Coupling for Optimal Performance

Proper installation of a motor coupling is essential to ensure optimal performance and reliability of the power transmission system. Follow these best practices when installing a motor coupling:

1. Correctly Match Coupling Type:

Select a motor coupling type that is suitable for the specific application and operating conditions. Consider factors like torque requirements, misalignment tolerance, and environmental factors when choosing the coupling.

2. Ensure Proper Alignment:

Achieve precise alignment between the motor and driven equipment shafts before installing the coupling. Misalignment can lead to premature wear and reduced efficiency.

3. Check Shaft Endplay:

Verify that the shafts have the correct endplay to allow for thermal expansion and contraction. Inadequate endplay can lead to binding or increased stress on the coupling and connected components.

4. Clean Shaft Surfaces:

Ensure that the shaft surfaces are clean and free of any debris or contaminants before installing the coupling. Clean surfaces promote proper coupling engagement and reduce the risk of slippage.

5. Use Correct Coupling Fasteners:

Use the specified fasteners, such as bolts or set screws, provided by the coupling manufacturer. Tighten the fasteners to the recommended torque values to secure the coupling properly.

6. Verify Keyway Alignment:

If the coupling has a keyway, ensure that it aligns correctly with the key on the motor and driven equipment shafts. Proper keyway alignment prevents rotational slippage and ensures efficient torque transmission.

7. Lubrication:

If the coupling requires lubrication, apply the appropriate lubricant as recommended by the manufacturer. Proper lubrication reduces friction and wear on coupling components.

8. Perform Trial Run:

Before putting the system into full operation, perform a trial run to check for any abnormalities or vibrations. Monitor coupling performance and check for leaks, noises, or other signs of issues.

9. Regular Inspection and Maintenance:

Conduct regular inspections and maintenance on the motor coupling and the entire power transmission system. Check for wear, alignment, and any signs of damage, and address any issues promptly.

10. Follow Manufacturer Guidelines:

Always follow the manufacturer’s installation guidelines and recommendations for the specific coupling model. Manufacturer guidelines provide essential information for optimal performance and safe operation.

By adhering to these best practices, you can ensure that the motor coupling functions efficiently and contributes to the overall performance and reliability of the mechanical system.

“`

Comparing Motor Couplings with Direct Drives and Other Power Transmission Methods

Motor couplings, direct drives, and other power transmission methods each have their advantages and disadvantages, making them suitable for different applications. Let’s compare these methods in terms of various factors:

1. Efficiency:

Motor couplings generally offer high efficiency in power transmission since they provide a direct mechanical connection between the motor and driven equipment. In contrast, direct drives can also be efficient as they eliminate the need for intermediate components.

2. Misalignment Compensation:

Motor couplings are designed to accommodate misalignments between the motor and driven equipment shafts, making them suitable for applications where misalignment is expected. Direct drives, on the other hand, require precise alignment between the motor and driven equipment.

3. Maintenance:

Motor couplings often have minimal maintenance requirements since they do not have intricate components. Direct drives can be maintenance-free as well since they eliminate the need for belts, chains, or gears.

4. Backlash:

Motor couplings typically have low or zero backlash, ensuring precise torque transmission. Direct drives also offer low or no backlash since there are no intermediate components to introduce play.

5. Cost:

Motor couplings are generally more cost-effective compared to direct drives, which may involve higher initial investment in specialized components. However, the overall cost may vary depending on the application and system requirements.

6. Space and Size:

Motor couplings are compact and can fit in tight spaces, making them suitable for applications with limited room. Direct drives may require more space, depending on their design and motor size.

7. Shock Absorption:

Motor couplings, especially those with elastomeric elements, can absorb shocks and vibrations, protecting the motor and driven equipment. Direct drives may not have the same level of shock absorption.

8. Torque Transmission:

Both motor couplings and direct drives are efficient in torque transmission. However, some direct drives may offer higher torque capacity for heavy-duty applications.

9. Installation Complexity:

Motor couplings are generally easier to install compared to direct drives, which may involve more intricate assembly and alignment procedures.

10. Application:

Motor couplings are versatile and can be used in various industrial setups, especially when misalignment compensation is required. Direct drives are commonly found in applications where high precision and direct mechanical connection are crucial.

Ultimately, the choice between motor couplings, direct drives, and other power transmission methods depends on the specific needs and constraints of the application. Each method offers distinct advantages, and selecting the most suitable option requires careful consideration of the application’s requirements, space limitations, budget, and maintenance preferences.

“`

Can a Damaged Motor Coupling Lead to Motor or Equipment Failure?

Yes, a damaged motor coupling can lead to motor or equipment failure if not addressed promptly. Motor couplings play a critical role in connecting the motor to the driven equipment and transmitting torque between them. When a coupling is damaged, several potential issues can arise:

- Reduced Torque Transmission: Cracks, wear, or deformation in the coupling can result in reduced torque transmission from the motor to the driven equipment. This may lead to inefficient operation and underperformance of the machinery.

- Mechanical Vibrations: Damaged couplings can introduce vibrations into the system, leading to increased wear and fatigue on connected components, such as bearings and shafts. Excessive vibrations can cause premature failure of these parts.

- Misalignment and Stress: If the coupling loses its ability to compensate for misalignment, it can subject the motor and driven equipment to increased stress and loading. This can result in premature wear and failure of bearings, shafts, and other components.

- Overload on the Motor: In certain coupling designs, damage may result in a loss of overload protection. Without the safety mechanism, the motor may experience excessive loads, leading to overheating and possible motor failure.

- Increased Downtime: A damaged coupling can cause unexpected breakdowns and unplanned downtime for repairs, affecting productivity and overall operational efficiency.

- Safety Risks: In extreme cases, a severely damaged coupling may disintegrate during operation, posing safety risks to personnel and surrounding equipment.

To avoid motor or equipment failure due to a damaged coupling, regular maintenance and inspection are crucial. Visual inspections, vibration analysis, and monitoring of coupling performance can help identify signs of damage early on. If any issues are detected, it is essential to replace or repair the damaged coupling promptly to prevent further damage and ensure the reliable operation of the machinery.

Proper selection of high-quality couplings, appropriate for the specific application and operating conditions, can also reduce the likelihood of coupling failure and its potential impact on the motor and equipment.

“`

editor by CX 2024-03-03